Tempered glass is different from standard glass and annealed glass. It is commonly referred to as safety glass and also known as toughened glass. It is referred to as toughened glass because it is up to four times stronger than standard glass. On some occasions, the strength can rise to become up to seven times stronger than regular glass.

It is referred to as safety glass because it is resistant to shatter and would require tremendous effort or impact to break. When it breaks, it does not pose a danger. It cannot cause injuries to people in the immediate environment because it does not break into large sharp glass shards. Instead, it breaks into dull pebble-like pieces that do not pose any threat of injuries.

Due to its durable and safety features, it is commonly used in environments and places where keeping people safe is of utmost importance. Safety glass is widely used in rear and side windows of vehicles, tub and glass shower enclosures, patio furniture, entrance doors, and glass kitchen cabinets, amongst others.

HOW IS TEMPERED GLASS MADE?

Glass tempering involves a series of steps and processes.

- Glass preparation

The first step is to prepare the glass panel for tempering. This is done because any amendment like edging or etching the glass is carried out after the heating process, it could lead to a reduction in strength of the safety glass.

The glass is cut into the preferred dimension. After cutting, the glass is scrutinized for imperfections. This step is vital as defects could cause the glass panel to break during the tempering process. The glass is polished on the edges with an abrasive to get rid of the sharp edges. The glass panel is then washed after the edge polishing process.

- The heating process

The next step is to take the glass panel through the heat treatment process. The glass panel is put in the tempering oven either as a continuous feed or as a batch. The glass is heated up to six hundred degrees Celsius. The standard of the glass industry is to be heated for up to six hundred and twenty degrees Celsius.

- The quenching process

Next is for the heat-treated panel to undergo quenching. Quenching is a high-pressure cooling procedure that lasts for only seconds. Air is blasted on the glass surface at high pressure from varieties of air nozzles in different positions. This cools the outer surfaces of the glass quickly.

The center tries to pull back from the outer surfaces as it begins to cool. This leaves the center in tension while the exterior surfaces move into compression. This is what gives the tempered glass its strength.

Glass breaks five times more quickly in tension than in compression. Annealed glass at six thousand pounds per square inch will break. Owing to federal specifications, toughened glass must be manufactured to meet a surface compression of ten thousand pounds per square inch or more. This makes a toughened glass break at twenty-four thousand pounds per square inch. This makes it a lot stronger than regular glass.

CHEMICAL TEMPERING

Another way to make toughened glass is to put the glass through a chemical tempering process. This is the process where ions are exchanged on the glass surface by various chemicals to create compression.

The chemical tempering process is not widely used because it is more expensive than the heat treatment process.

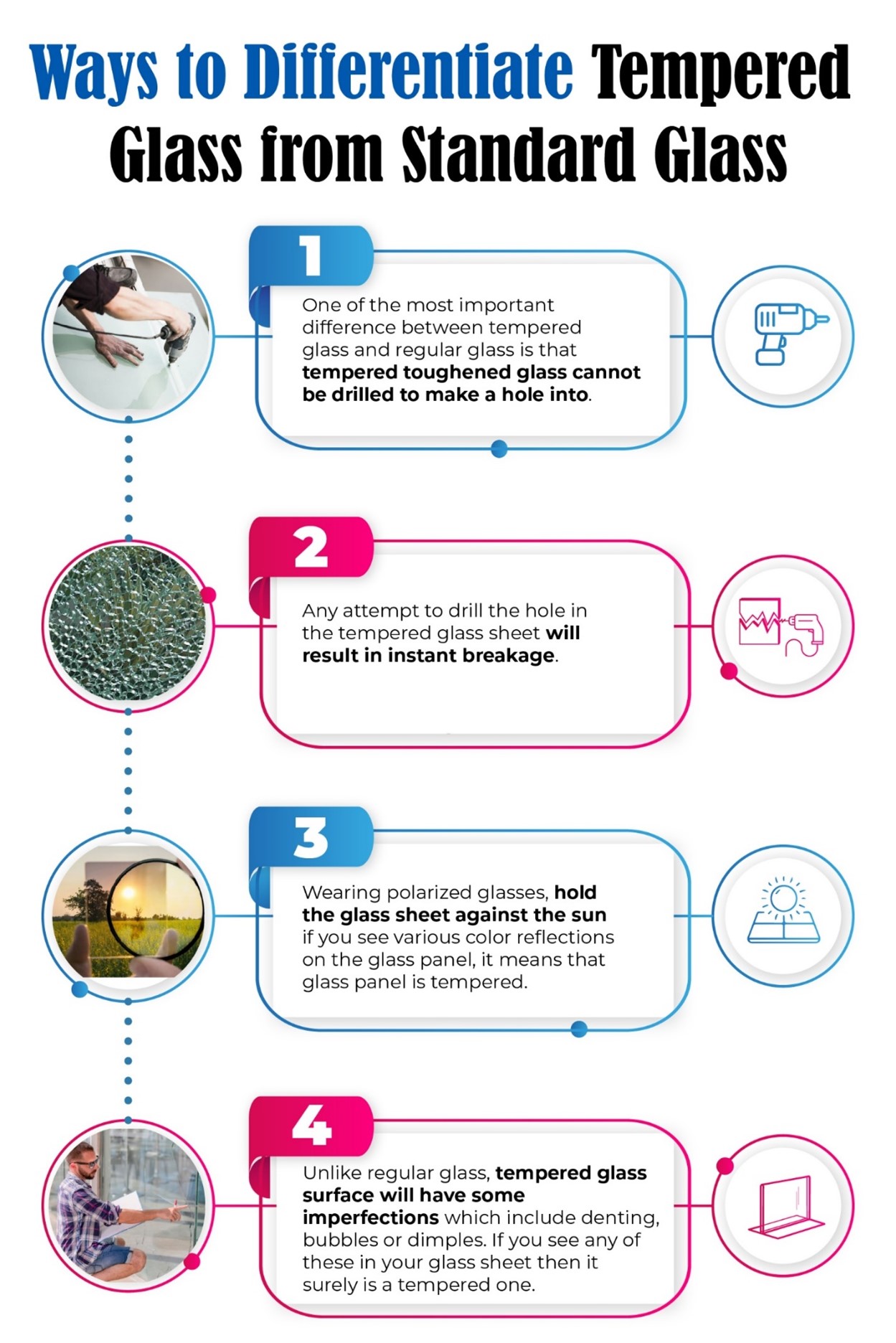

WAYS TO DIFFERENTIATE TEMPERED GLASS FROM STANDARD GLASS

Below are tests that can be carried out to differentiate toughened glass from standard glass.

- Drilling a hole into the glass

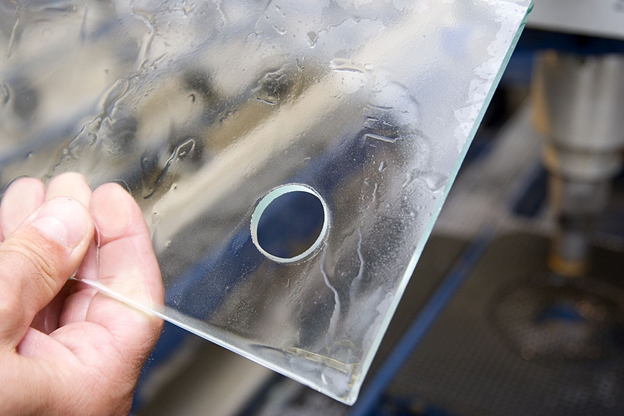

One of the most important differences between a toughened glass and regular glass is that toughened glass cannot be drilled to make a hole. If you are able to drill through a glass panel, the glass panel is either an annealed or standard glass and not a tempered glass.

A hole cannot be drilled into tempered glass. Any attempt to do this will cause the glass to explode instantly right through the effort. Does this mean that holes cannot be made into toughened glass? No, holes can, but the holes would have been drilled into the glass before taking the glass through the tempering process.

Manufacturers will include holes where these are necessary for the glass design, as requested for you to use instead of drilling. Drilling holes after the glass has been tempered will cause instant breakage.

- Check through polarized sunglass

There are two ways to check if the glass is tempered using polarized sunglasses.

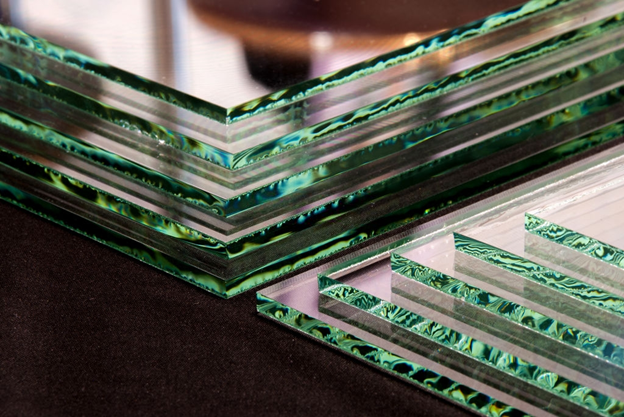

To conduct the polarized sunglass test, the first thing to do is to place a smartphone or laptop with the display on in the background. Hold the glass panel you want to test against the smartphone or laptop surface. On the other hand, hold the polarized sunglass in front of the glass panel with the laptop or smartphone screen vividly in the background.

Move the polarized sunglass sideways. The first thing to watch out for is that the sunglass should reflect different colors as you move from one side to the other. When various color reflections show on the polarized sunglass, the glass panel is tempered glass. However, if the sunglass simply darken when you move from side to side, it is just regular glass.

The second way to detect or to know what is tempered glass to move the notch if the glass has one beneath the polarized sunglass. If there is a stretch of colors like a rainbow around the glass notch, the glass panel is a genuine toughened glass.

- Look into small imperfections: dimples or bending

Unlike regular glass, a toughened glass that has gone through the tempering process will sport some imperfections. These include bending, warping, and dimples. There are small impressions on the surface of toughened glass. These impressions came about through how the glass was handled through the heat tempering process.

This could be because of the tongs used to pick up the heated glass from the heat oven during the heating process. The tongs will leave tiny impressions on the surface of the glass that can be identified when the glass surface is observed closely.